Dedicated Design Facilities & Equipment

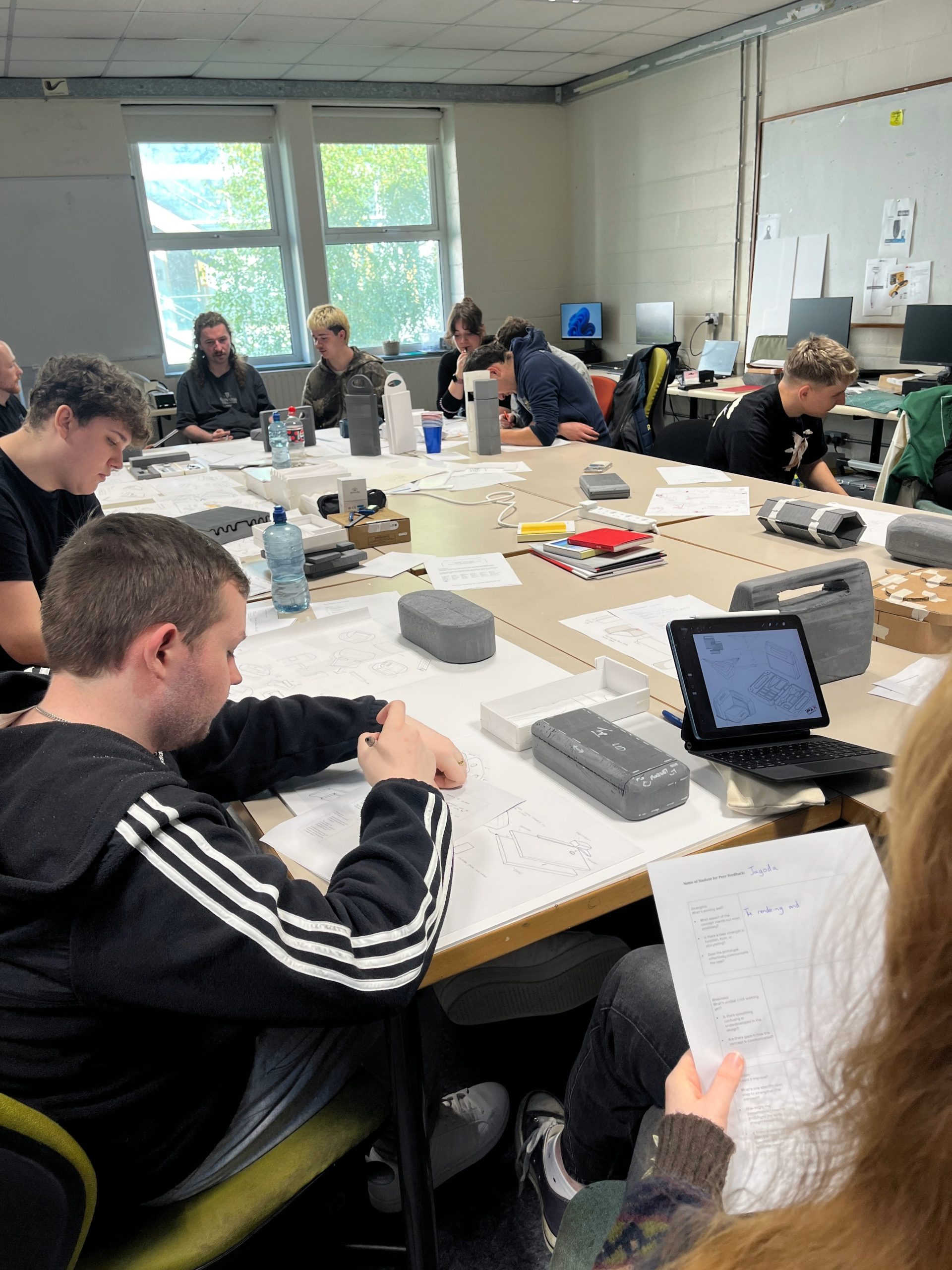

As a Product Design student at SETU Carlow, you’ll study in a fully dedicated, purpose-built environment designed around how designers actually work: making, testing, iterating, and refining ideas through hands-on practice.

All facilities and equipment are exclusively for the Product Design course and are located together. This includes four dedicated studios (one for each year group), the workshop, and digital fabrication spaces, all positioned beside each other and next to the design staff offices. This layout supports studio culture, easy access to equipment, and close interaction with staff.

You’ll have access to a wide range of professional-grade tools and technologies, including:

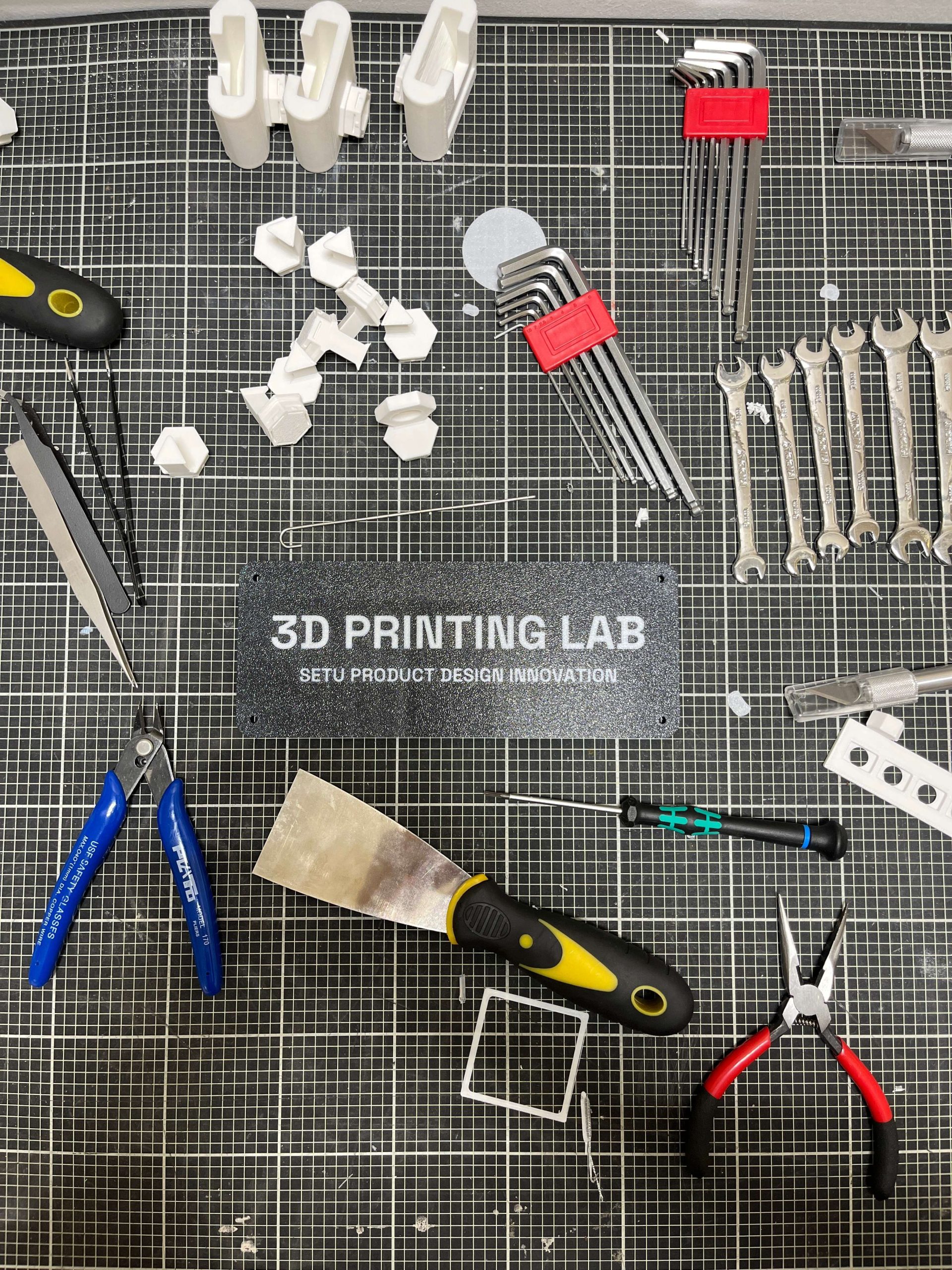

3D Printing & Digital Fabrication

- Student-led 3D printing lad

- 3D printer material recycling systems

- Desktop CNC machines

- Laser cutter

- Vacuum former

- Desktop injection moulding equipment

Workshop & Making Facilities

- Band saws, lathes, and extensive hand tools

- Professional spray booth

- Foam wire cutter and foam-working tools

- Acrylic heating and forming equipment

- Wood steam chamber

- Sewing machines for soft goods and textiles

Design Research, UX & Emerging Tech

- 3D scanners and material scanners

- Eye-tracking glasses

- VR headsets

- Interactive screens and iPads for UX/UI design

- Wacom sketch tablets

Electronics & Prototyping

- Arduino and Raspberry Pi kits

Human-Centred Design

- Extensive empathy and simulation toolkit

- Support inclusive and user-centred design

What this means for you is simple: you won’t be waiting for access or learning design only in theory. You’ll work in a space where making is part of everyday studio life, building skills, confidence, and a strong portfolio through constant hands-on experience.

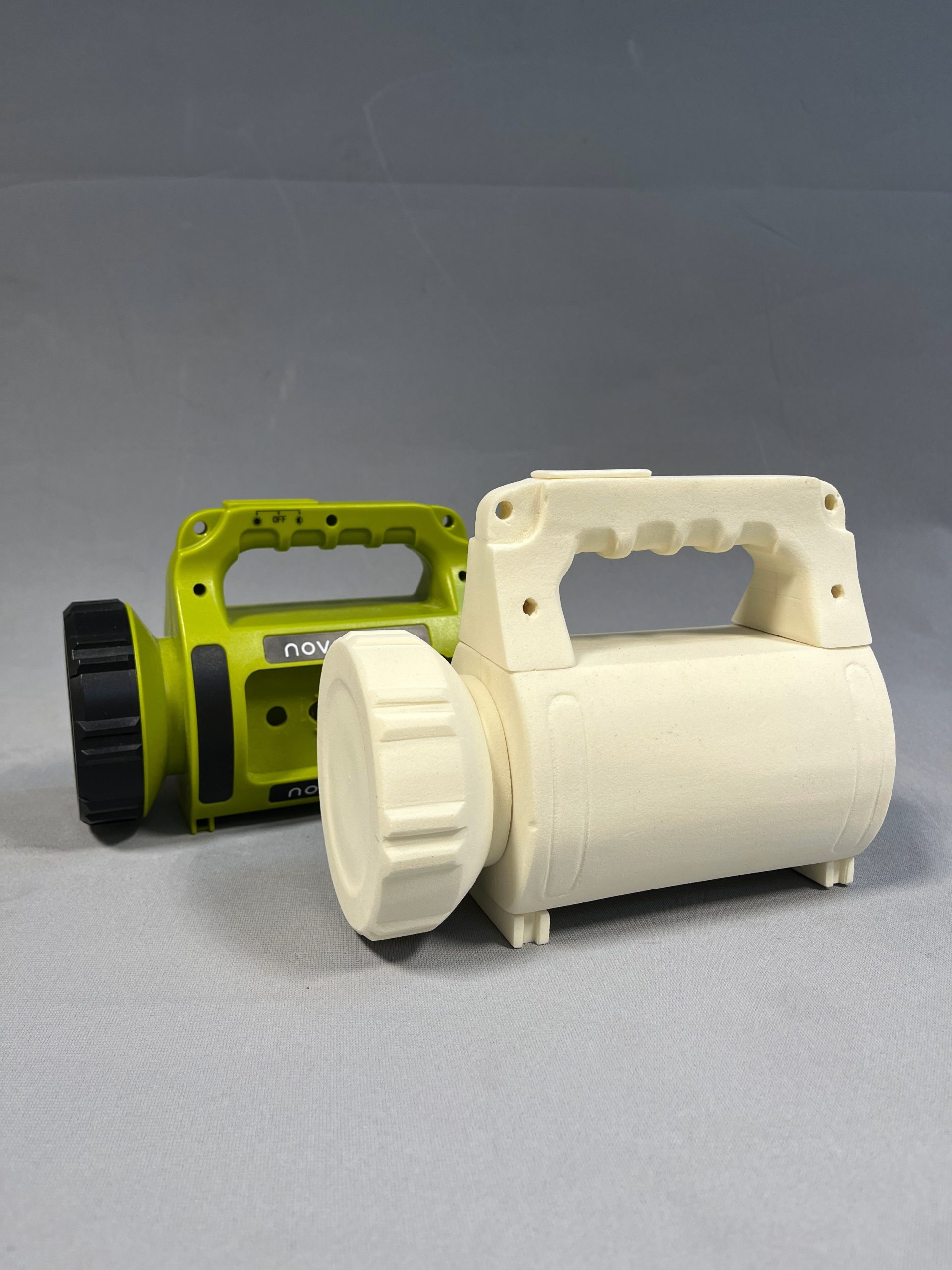

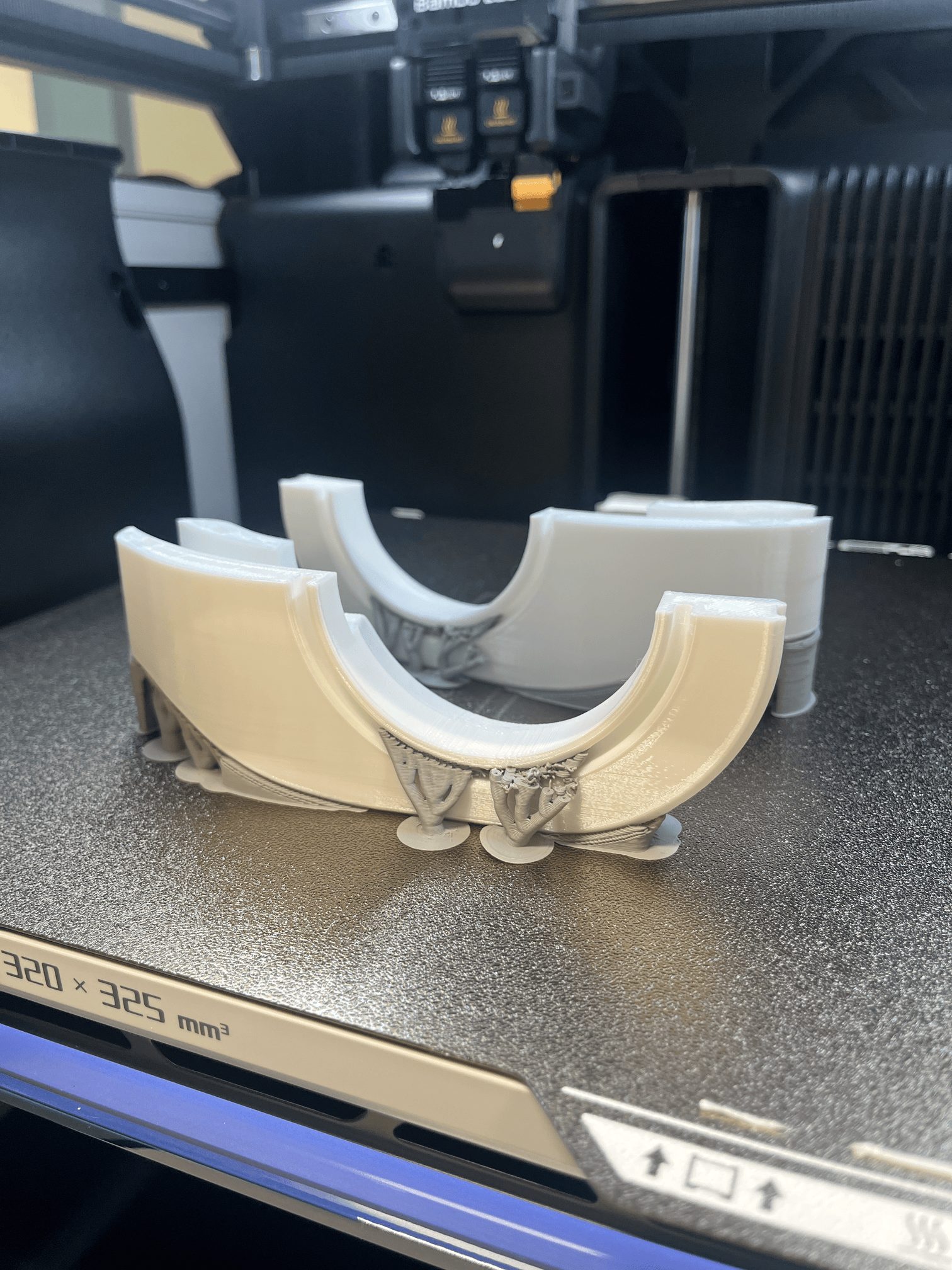

3D Printing & Digital Fabrication

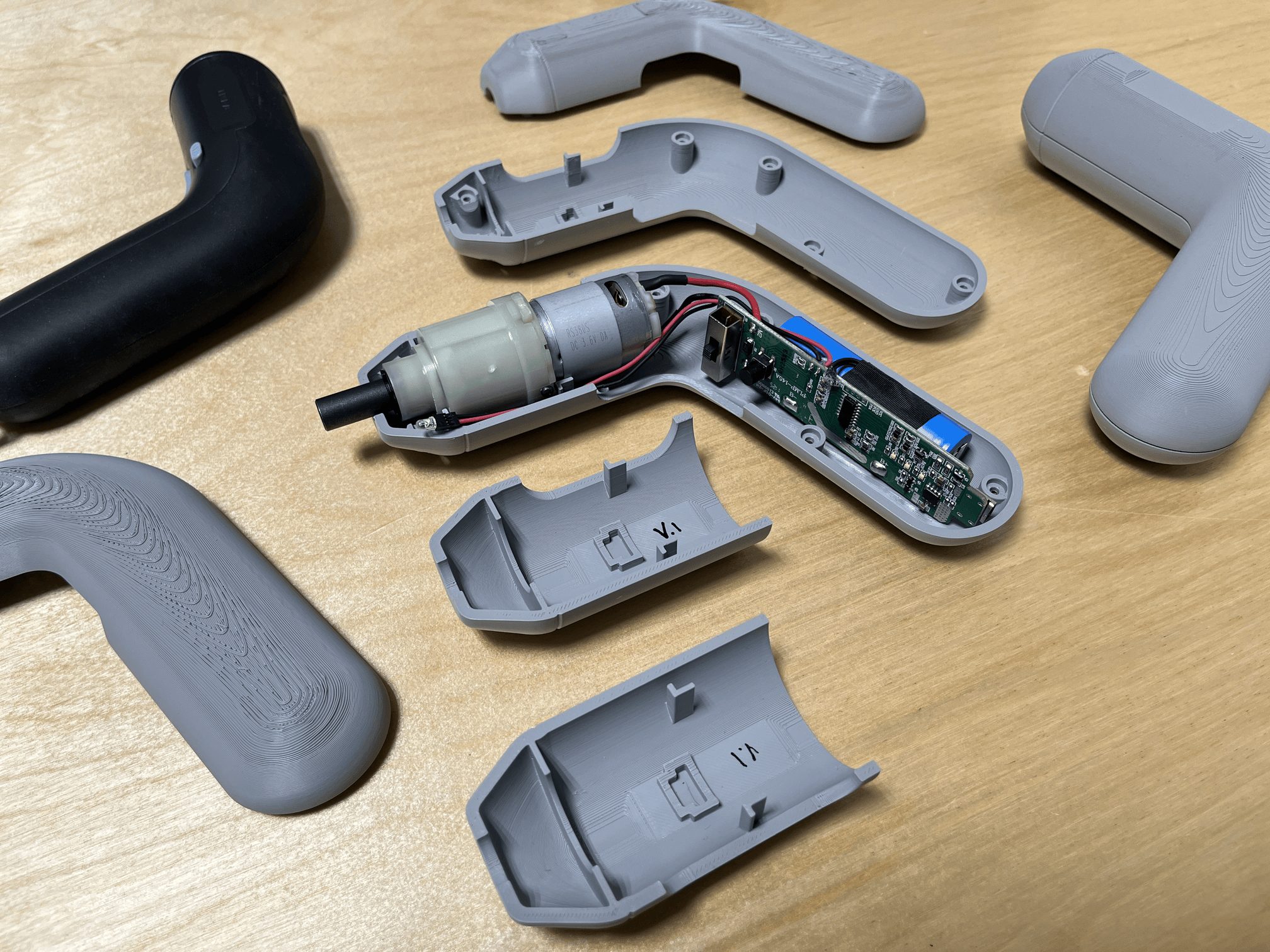

As a Product Design student at SETU Carlow, you’ll have open access to a full 3D printing and digital fabrication lab right beside the studios, so you can move quickly from idea to prototype as part of your everyday workflow.

The lab includes 15 state-of-the-art Bambu Lab printers (A1, X1 Carbon, H2D) and a fully integrated materials recycling system. You’ll receive training in 3D printing (file prep, materials, printing, troubleshooting, finishing), then you can use the lab independently to support your projects.

Because the lab is student-led, you’ll learn through doing, building technical confidence, iterating faster, and producing higher-quality prototypes and portfolio work, with staff support always close by.

Workshop & Making Facilities

The Product Design workshop at SETU Carlow is where you learn design through making. Students receive 4 hours of dedicated workshop access each week, supported by design lecturers and technical staff, so you can build skills safely and confidently.

In first year, you’re fully trained on workshop equipment and core processes, learning how to work with key materials including foams, card, sheet materials, plastics, metals, and wood. You’ll also develop finishing skills, including painting and spraying in a professional spray booth, helping you produce higher-quality prototypes and presentation models.

A dedicated soft modelling area is available to all students when required, supporting quick form exploration and early-stage prototyping as part of your studio workflow.